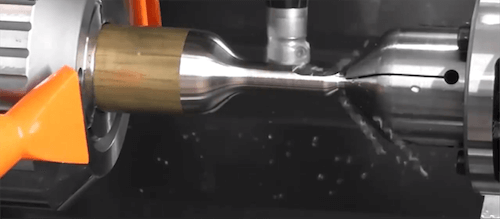

A Swiss style lathe is a type of machine that allows the part to move in the z-axis while the tools keep stationary. The bar stock is held by the collet that is recessed behind the guide bushing and will not directly be exposed to the lathe bed and the tooling, so the material can be turned within the machine rapidly and tightly, this eliminates the deflection and increases the accuracy.

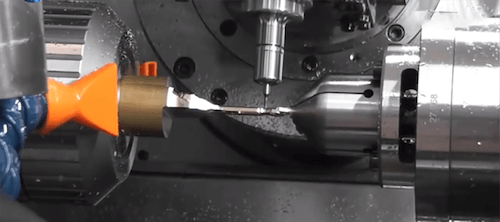

Furthermore, Swiss turning machines can perform several operations simultaneously in multiple zones, whereas a traditional lathe typically only performs one operation at a time.

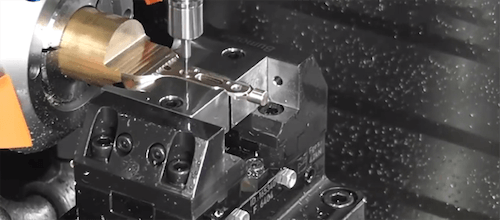

The availability of rotating tools gives Swiss-type machines the ability to produce other types of features on a part such as across holes or milled flats. These machining capabilities allow a complex part to be produced in a single machine.The combination of high precision and high production volume make Swiss machines a critical piece of equipment for shops that must produce a large volume of small and intricate parts with little margin for error.