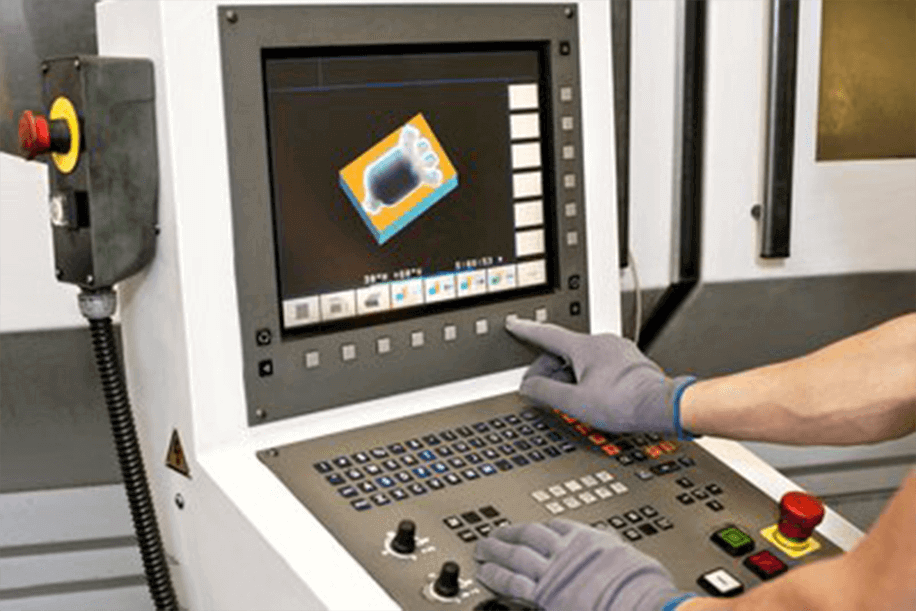

CNC Milling is a precision machining process that uses rotary cutting tools to remove material from a workpiece. The cutting tools move around the workpiece in a multi-axis motion, controlled by computer numerical control (CNC) programs.

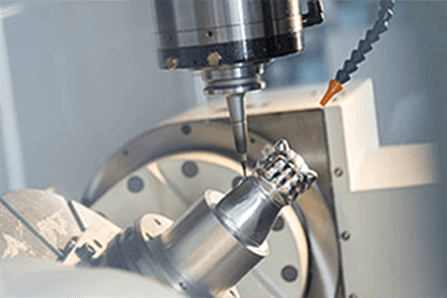

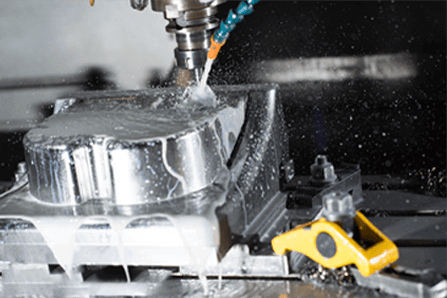

During the milling process, the workpiece is secured in a fixture or a vise, and the cutting tool removes material from the workpiece to create the desired shape or feature. CNC milling machines are capable of producing a wide range of complex parts, including those with irregular shapes, contours, and intricate details.

The CNC milling process is widely used in industries such as aerospace, automotive, medical, and electronics. It offers numerous advantages, including high precision, accuracy, repeatability, and speed. CNC milling machines can work with a variety of materials, including metals, plastics, composites, and wood.

To ensure the highest quality of CNC milling, it is important to use the right cutting tools, workholding devices, and cutting parameters. A skilled machinist can optimize the milling process to achieve the best results for each specific application.

In summary, CNC milling is a versatile and precise machining process that is widely used in modern manufacturing. It offers numerous benefits, including high precision, accuracy, and repeatability, and is capable of producing complex parts with a high degree of efficiency.