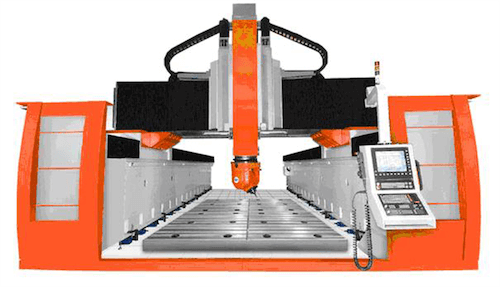

5-Axis CNC Machining is a technique of machining using machines with five rotating axes. Compared with traditional 3-axis CNC machining, 5-axis CNC machining has higher precision and a wider range of applications.

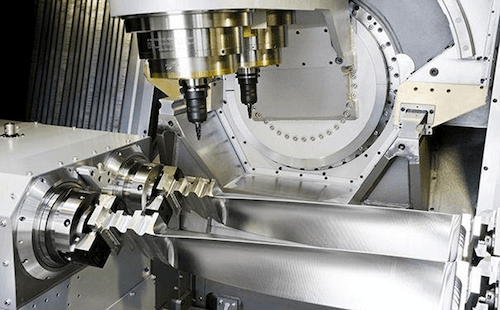

In 5-axis CNC machining, the tool can move along the X, Y, and Z axes, while also rotating around the X and Y axes. This extra rotation axis allows for more freedom in controlling cutting angles, allowing for more precise machining of complex-shaped parts. 5-axis CNC machining can be used for machining very complex geometric shapes, such as turbine blades, ducts, molds, etc., and has high efficiency, high precision, and high-quality machining capabilities.

5-axis CNC machining typically requires higher technical expertise and higher costs, but it is indispensable for applications requiring high precision and complex parts. Therefore, 5-axis CNC machining is widely used in aerospace, automotive, medical, mold, and other fields.