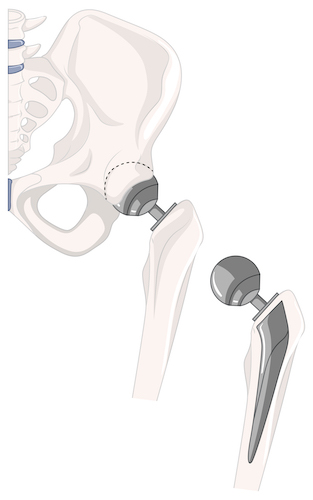

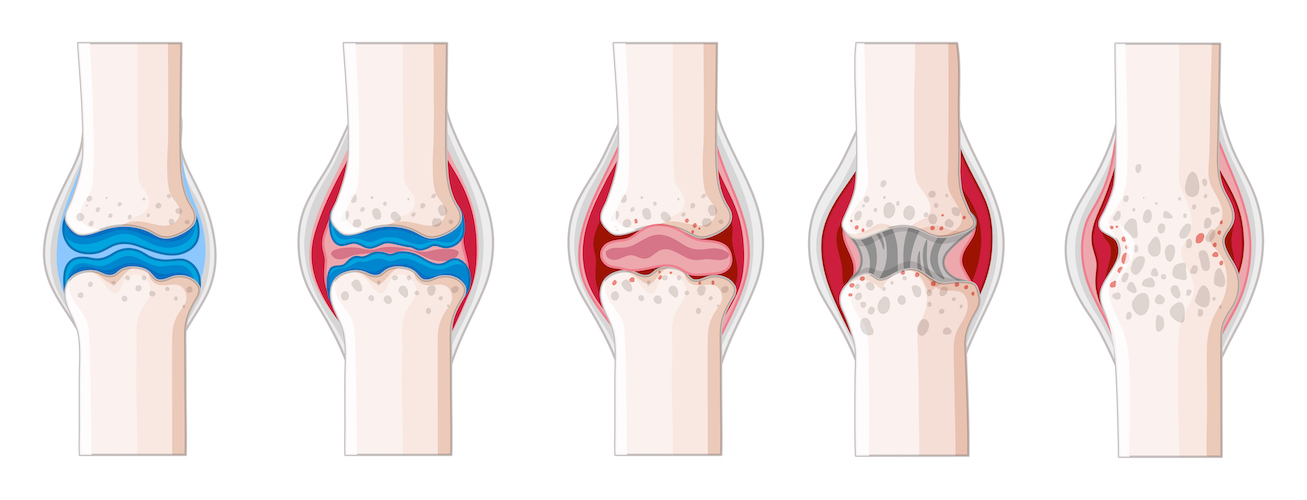

Artificial joint’s function is to replace the patient's original joint, such as the knee joint, hip joint, etc., restore joint function and alleviate pain. As Artificial Joint is directly implanted into the body, the manufacturing quality and material selection are crucial.

HME Machining utilizes 5-axis CNC machining to ensure the efficiency & progress of the joint’s complex shape. Manufactured from titanium alloy and joined with plastics to reduce friction and wear during motion, achieving optimal biocompatibility. The combination of sandblasting, polishing and spraying surface treatment processes aims to increase the friction and adhesion between the surface and bone, reduce stress, and promote postoperative healing and growth. The surface roughness of the final product is 0.4 microns, with a tolerance of ±30 microns, and a friction coefficient of 0.1.