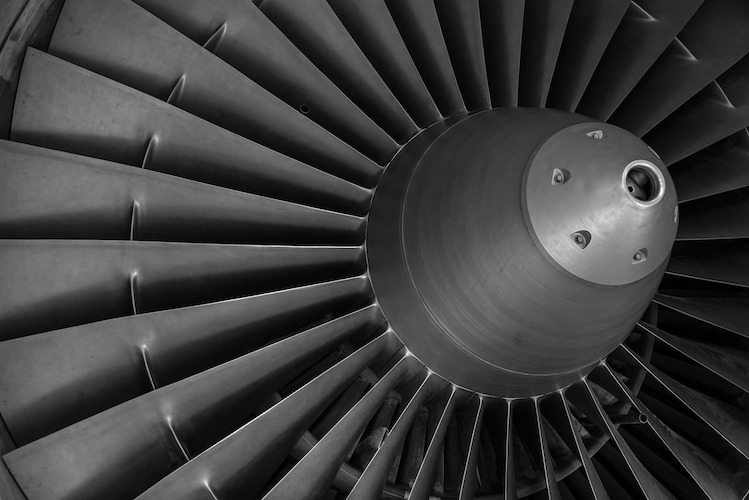

Turbine blades in aircraft engines are critical components that require high precision and quality, with tolerance ranges typically in the microns. Precision is crucial for engine performance and lifespan, with manufacturing errors potentially leading to engine malfunctions, shortened lifespan, or even accidents.

HME Machining utilizes 5-axis CNC machining to meet these exacting standards, and titanium alloy is used for its high strength, temperature stability and corrosion resistance in harsh engine environments. Sandblasting is employed to create a smoother surface, reducing aerodynamic friction and noise. The final product boasts a surface finish of 0.2 microns and a tolerance of ±25microns .